AUTO PRIMER

By nature a centrifugal pump is not self-priming, but there is a simple solution that involves combining a centrifugal pump and an open turbine with a priming tank. This centrifugal pump, which therefore accepts suspensions without difficulty, is transformed, thanks to this device, into an automatic priming pump.

THE PRINCIPLE OF PRIMING IMPLEMENTED BY THE DEPRESSION OF A CAPACITY GUARANTEES A PERFECT PROTECTION AGAINST POSSIBLE LEAKS.

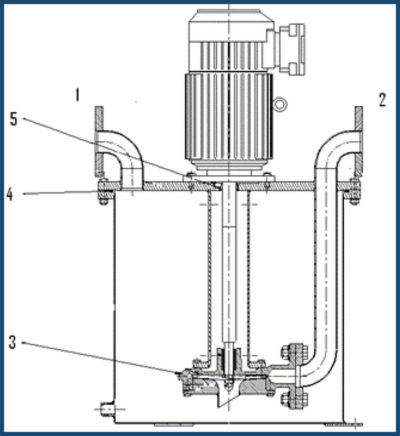

The pump is therefore a vertical centrifugal pump immersed in a tank. This is waterproof thanks to the following elements:

- (4) tank seal

- (5) dry sealing when passing through the shaft

SYSTEM OPERATION

As with all self-priming pumps, the TANK MUST BE FILLED BEFORE THE FIRST USE, the pump is then embedded in the liquid. Under these conditions, it can be started in order to convey the liquid in the discharge pipe (2). At the same time, the level in the tank decreases and creates a depression (by increasing the volume available for the gaseous sky). When this negative pressure reaches a value corresponding to the height of the suction pipe connected in (1), the pump starts.

When the pump is stopped, the vacuum in the tank automatically fills it by using the contents of the piping placed at the discharge (2). This allows the pump to be ready for the next start.

SEALING

To ensure priming, the vessel is kept under vacuum. This is therefore permanently in negative pressure or, at least, at atmospheric pressure when the pump is stopped. The sole purpose of sealing the passage of the shaft (5) is to prevent the air from entering the tank, and not the liquid to escape.

This pump therefore has the interesting feature of NEVER able to leak liquid away from the exterior even in the event of a leakage defect. There is a “clean” pump that keeps the environment safe in all circumstances.

Since the leakage at the passage of the shaft is a gas-gas seal, SIMPLY LUBRICATED LUBRIC RINGS ARE USED (photo). For some applications, a single or double mechanical seal may be recommended.

IMPLANTATION & USE

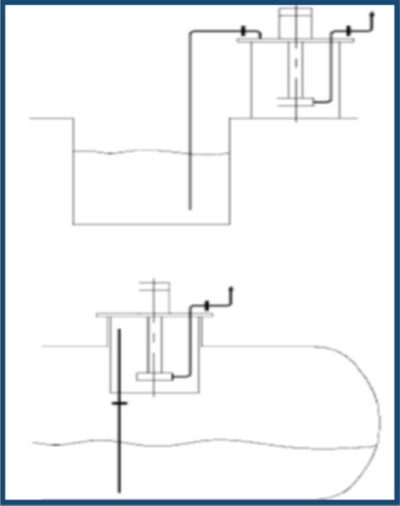

The implantation of such a pump is, for example, a mounting in the edge of a pit (FIG. 2). It can, however, be mounted directly into a tank manhole where it ADVANTAGES A VERTICAL CENTRIFUGAL PUMP WITH AN IMMERSED TREE LINE.

The limits of use of this pump are obviously those imposed for all pumps by the laws of physics: the maximum suction height depends on the vapor pressure of the liquid and its specific weight and the NPSH of the pump.

SUCH A PUMP IS CAPABLE OF PUMPING UP TO 8M OF THE WATER AT 20°C OR UP TO 4M OF THE 96% CONCENTRATED SULFURIC ACID.