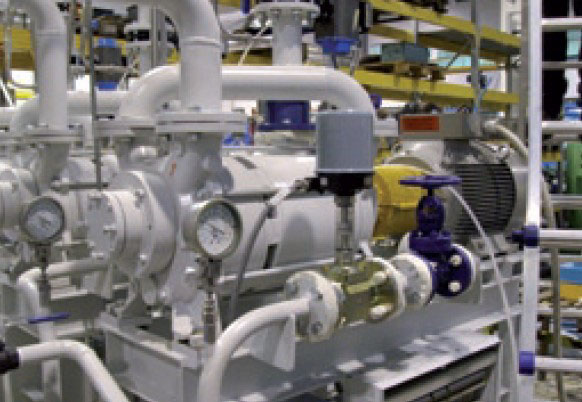

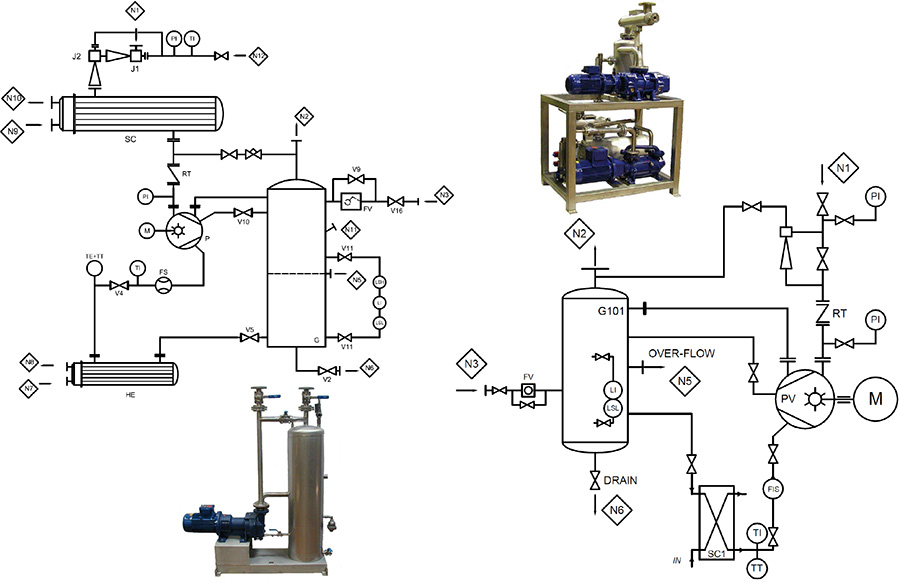

The GV vacuum pump skids can integrate into a liquid ring pump, a gas injector and/or a mechanical booster pump having a control system and a recycling system for closed loop liquids..

With no discharge, the vacuum pump skids do not pollute and comply with all the European environmental protection regulations, as well as the ATEX directive.

Permanent cooling efficiently contributes to the system’s durability and frees business owners from the constraints linked to installing bulky and costly fire prevention devices.

Taking up the same floor space as a self-lubricating pump, but costing almost twice as less, this new system allows real savings in cost as much as in size, while complying with all the current prevailing standards.

- Flow rate: 3 to 50 000 m3/h

- Operating vacuum: Down to 1 mbar (liquid ring + injectors ) 10-5 mbar (liquid ring + Injectors+ Mechanical booster)

LIMITS OF USE

- Flow: 200 to 15 000 m3/h

- Vacuum obtained: 10-5 mbar

- Differential pressure: 30/130 to 800 (with by-pass) mbar

Operating principle

When used with a liquid ring pump, the mechanical booster pump allows reaching lower levels. Actually, it functions much like a lobe type blower and permits reaching vacuum levels up to 10-5 mbar. You can also choose to integrate a by-pass system into the pump that expands the possibilities for use.

LIMITS OF USE

- Flow and vacuum obtained: No limit

- Compression factor: # 10

Operating principle

An injector is an industrial tool generally used to create a vacuum. It functions using the Venturi effect. A gas is ejected at top speed at the venturi inlet (generally water vapour) and suction is produced at the level of the constriction.