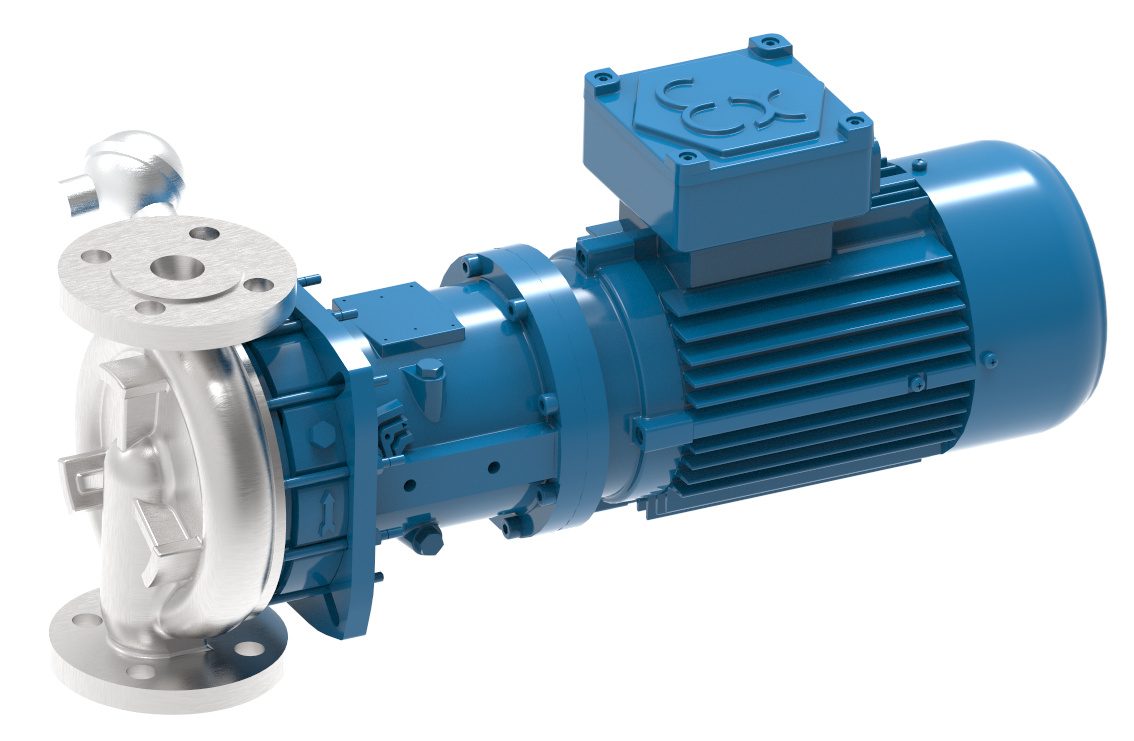

The centrifugal pumps in the LGF series are specially designed for industrial use of thermal fluids in a spirit of environmental protection.

The LGF pumps are designed to avoid any leaks, even fugitive ones, of products pumped outdoors. This specific tightness is obtained using magnetic coupling that can be used with either hot or cold products.

Because of their monoblock design and In-Line, assembly, LGF pumps take up limited space, which makes their integration into compact « »Skid » » assemblies much easier

Thermal fluids – Skid manufacturers – Engineering companies – Chemical and fine chemical industries – Pharmaceutical industry – Heat transfer fluids (environmental protection)

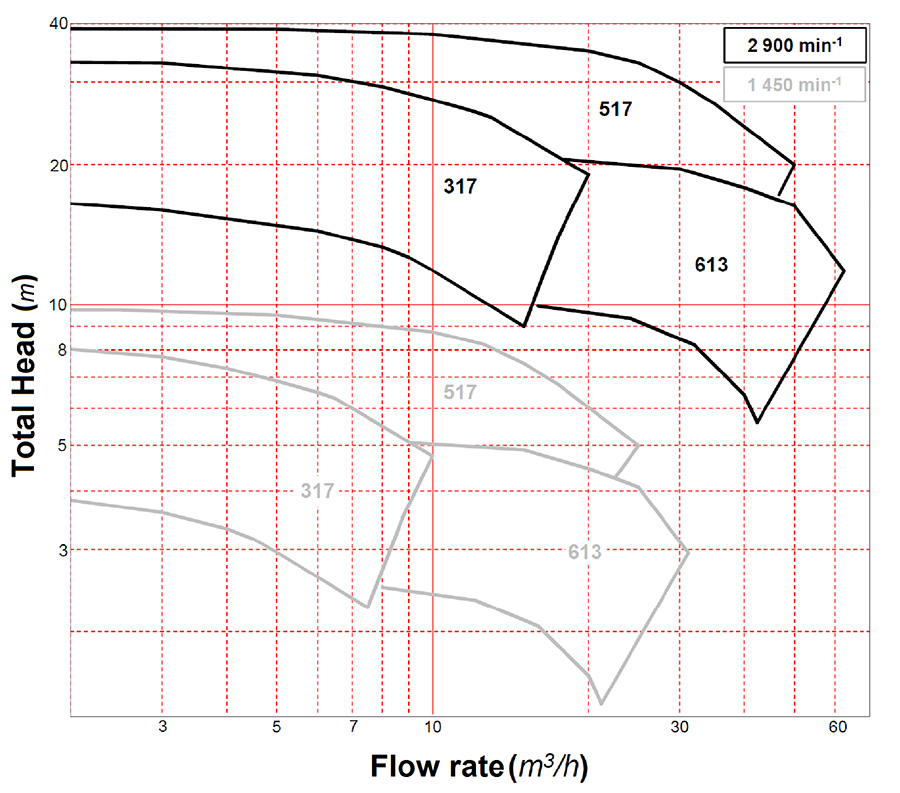

- Flow rate: 1 to 60 m3/h

- Total head: < 40 m

- Operating temperature: – 30°C to + 300°C

- Operating pressure: < 10 bar

- Speed: < 3600 min-1

- ATEX certification: II 2 G II B T2/T3/T4

Please contact us to see the 1450 rpm/min speed selection curves.

OUR STANDARDS :

- Pump body 316L Cast Iron/Carbon steel

- Cover/diffuser/flange Nodular Cast Iron

- Impeller Nodular Cast Iron

- Shaft 329LN Stainless steel

- Gasket Aramid

To better respond to your requirements, our expertise in the metalworking industry is at your service: Hastelloy, Duplex, Inconel, Monel, Titanium…

- Type Magnetic coupling

- Can Non-magnetic alloy

- Mobile mounted on block Silicon carbide

- Magnet material Samarium cobalt

- Lubrication Process fluid

- Can gasket FKM (ex: FEP covered)

We’ll help you define the best type of assembly and dynamic sealing adapted to your application.

Motor

- Three-phase (other voltage on request)

Paint

- Primer + epoxy paint RAL # 5017