Validation of the hydraulic performances

Concerned with guaranteeing the best performance of our equipment (either after an intervention or on new equipment), we validate the hydraulic features and dynamic behavior of our pumps on our test bench.

The test bench was re-built in 2009 and includes:

- A frequency driver

- A mag meter

- Vacuum pump to determine the required NPSH

- Analogue pressure sensors with digital display

Diagnostic & Reconditioning

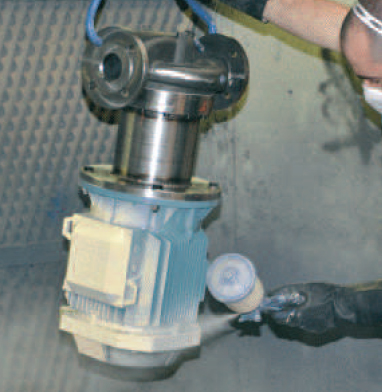

A 700 m² workshop equipped with a test bench, electrical cabinet with frequency driver, overhead bridge crane, and paint booth…all this enables us to guarantee the repair and maintenance of your pump equipment following the best practices.

Our skills

In order to provide optimum service, our maintenance teams undertake the operations in our workshop by combining their technical skills, high-responsiveness and qualifications.

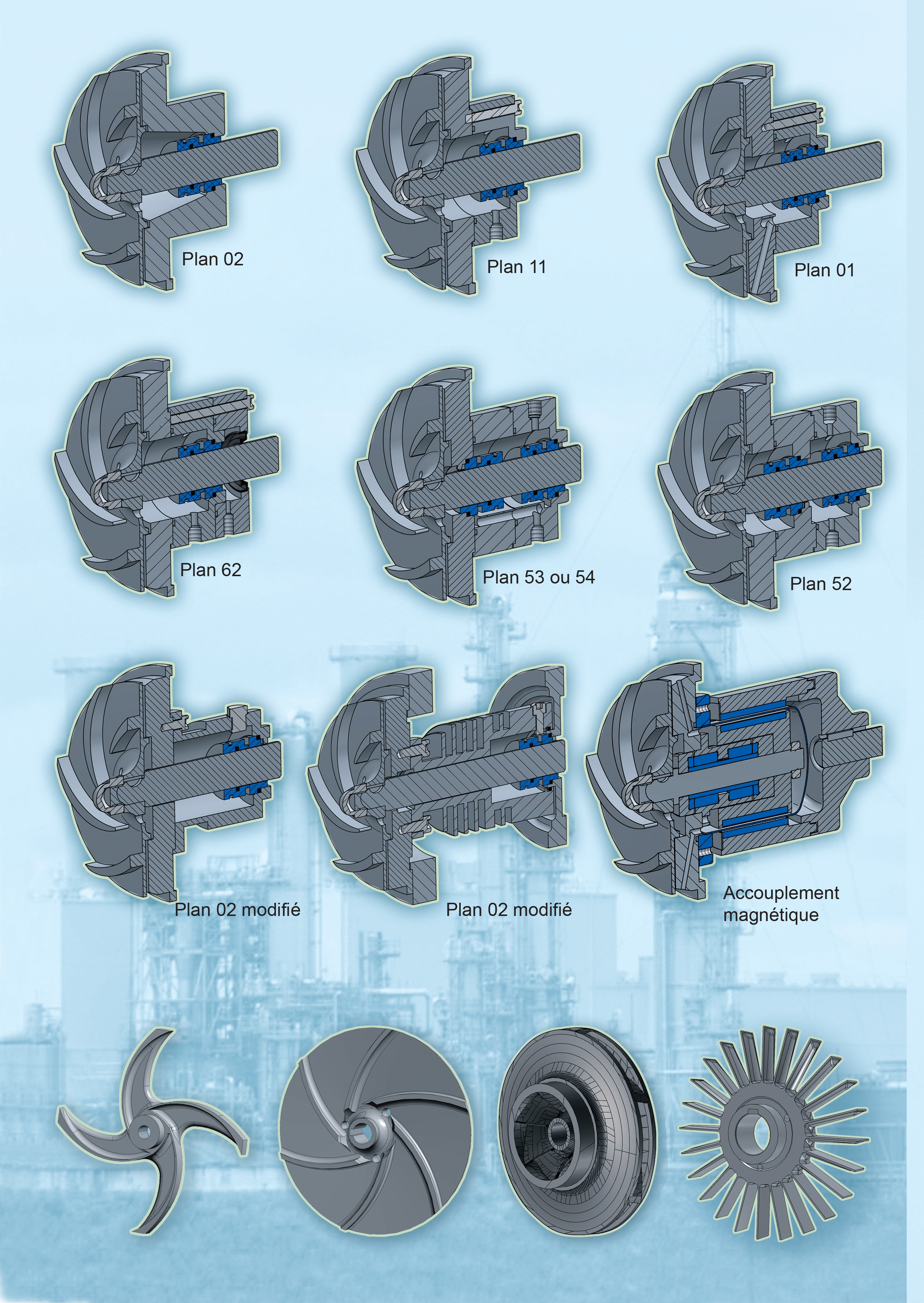

Our mastery of fluid mechanics provides sure and reliable expertise to our customers as well.

Our electronic and measuring equipment allows us to verify hydraulic features on centrifugal pumps (either ours or our competitors’) after each intervention.

Peace of mind and performance monitoring.

Repair and Maintenance Service

In 2017, Pompes Grosclaude is investing in a specialised Repairs and Maintenance service. Jacques COSSUTTA has been an operating technician in the industrial pump sector for 20 years, his expertise is now leading him into an advisory role. Pompes Grosclaude can deal with any brand of centrifugal and vacuum pumps.

Put simply our goal is to share our expertise with our partners. The quality and durability of our products have been proved. Today, we want to prove that Pompes Grosclaude’s quality mission does not stop at the fabrication stage but extends to the maintenance and repair of its products and those of its competitors.

Jacques COSSUTTA is, therefore, your expert representative. His mission is to supply a made-to-measure service on-site or in our workshop. He is also responsible for following and chasing up ongoing repairs.

He can be contacted using the following contact details:

The following two documents, filled in and signed, are needed for all repairs:

Our Workshop

Our workshop is dedicated to quality.

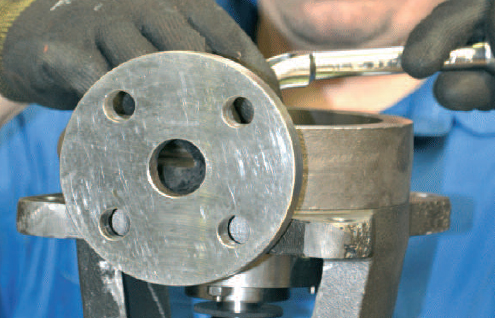

Our diagnostic tools mean that we can repair your centrifugal pumps in strict accordance with the rules of the trade. Our professional team is at hand for all repairs and compliance upgrading. At our 700m² workshop near Lyon, France, we take all your equipment for analysis, overhaul and testing. The reports sent to you are drawn up in a technical spirit that respects your individual industrial process.

Our resources are at your disposal:

A 4-tonne bridge, a test bench with measuring instruments, a paint booth and machining equipment. All of these tools mean that we can successfully respond to your requests.

Our mastery of the chemical and industrial production processes enable us to maintain noble metals such as stainless steel, Uranus or Hastelloy. After each intervention you will be guaranteed with pumps that meet your requirements.

Phone support (We speak English): Tel. (33) 4 72 37 94 00 (2)

A technical team is available to respond to your questions

A customer-focused team

Don’t hesitate to contact us for any questions you have regarding :

- Specifications to give to us

- Technical validation on the operation of our pumps

- Confirmation of deadlines for pending orders

- Availability of spare parts

- A spare part for one of our older pumps…