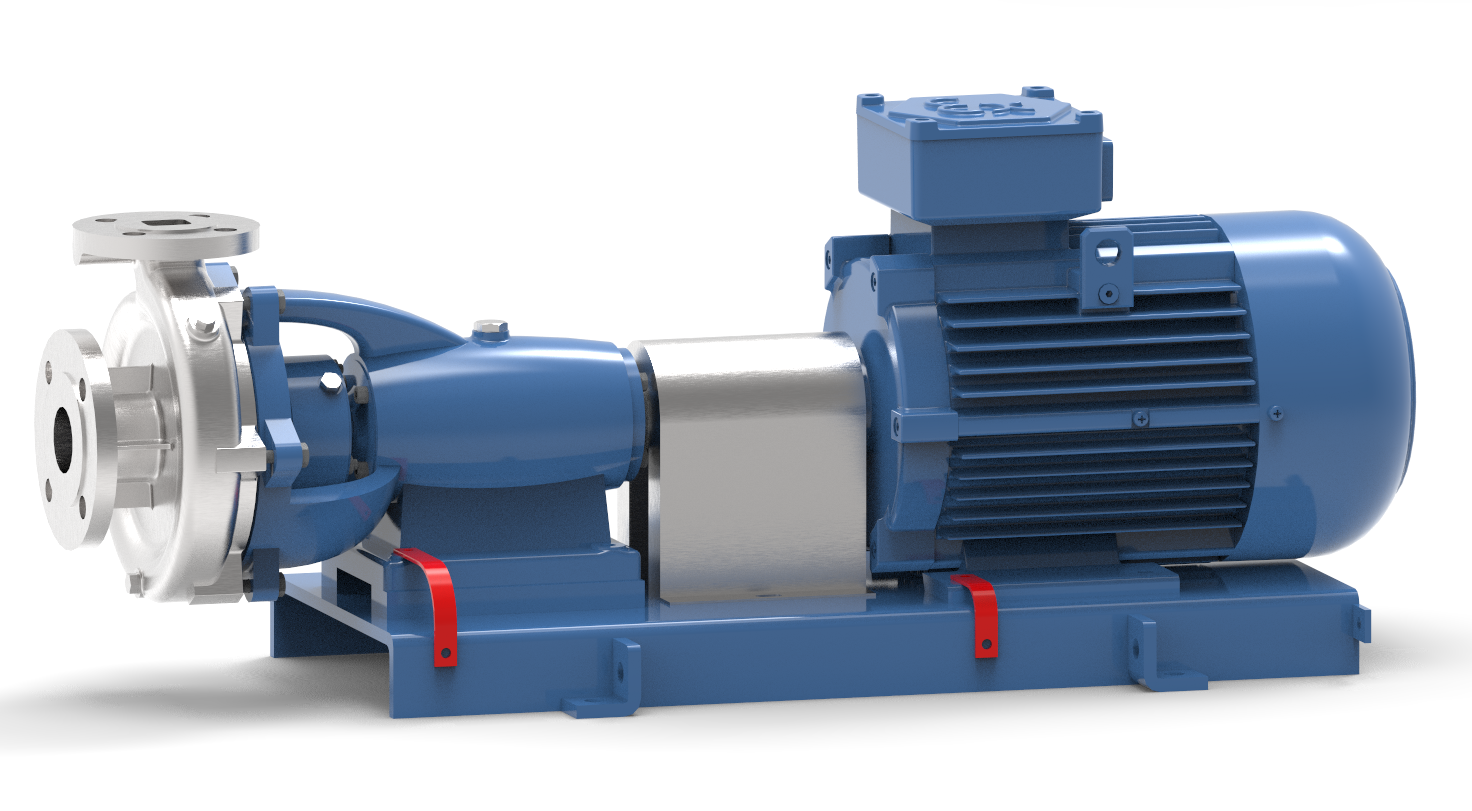

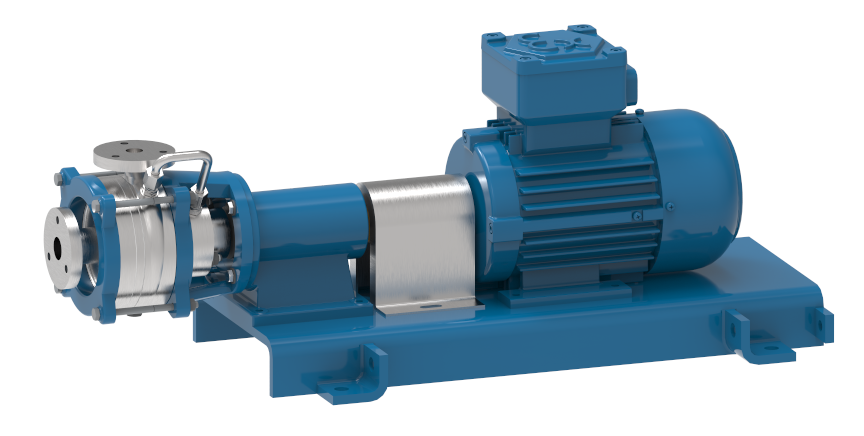

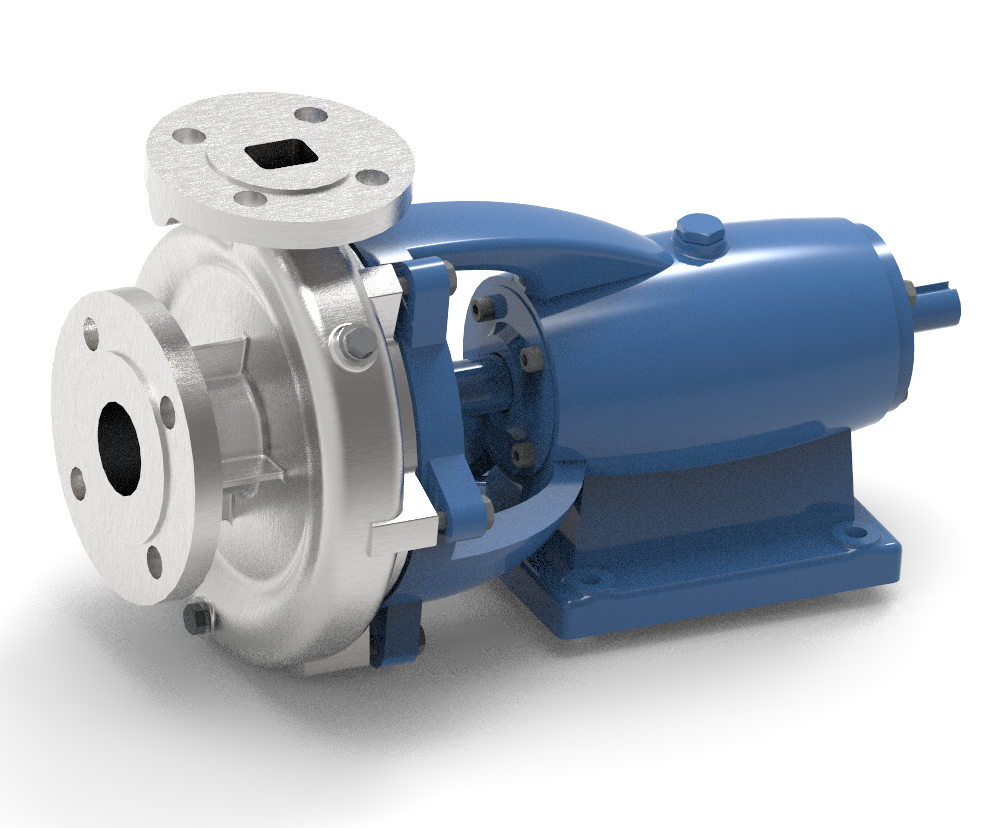

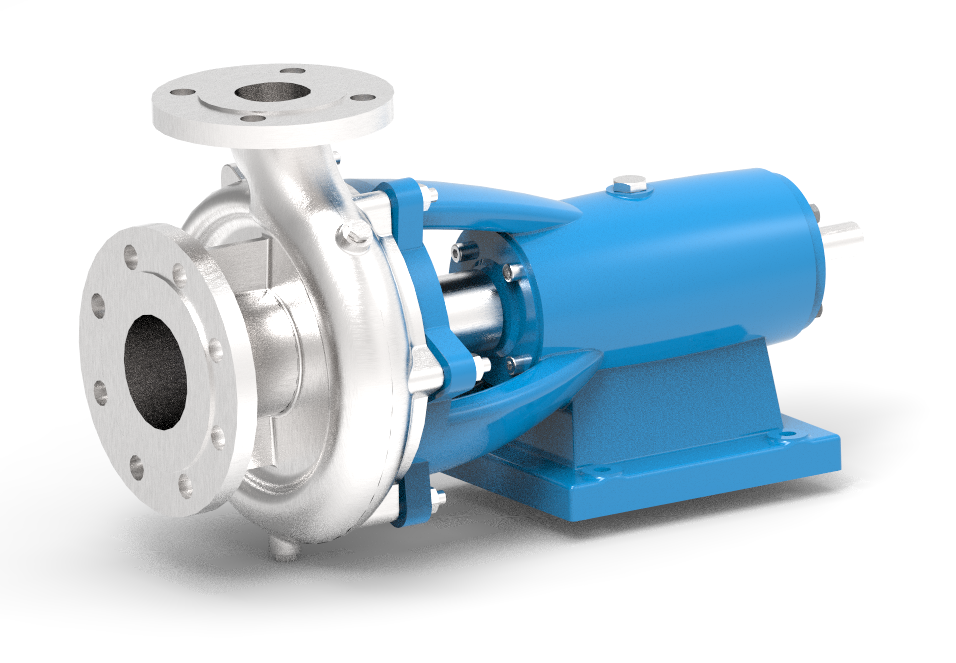

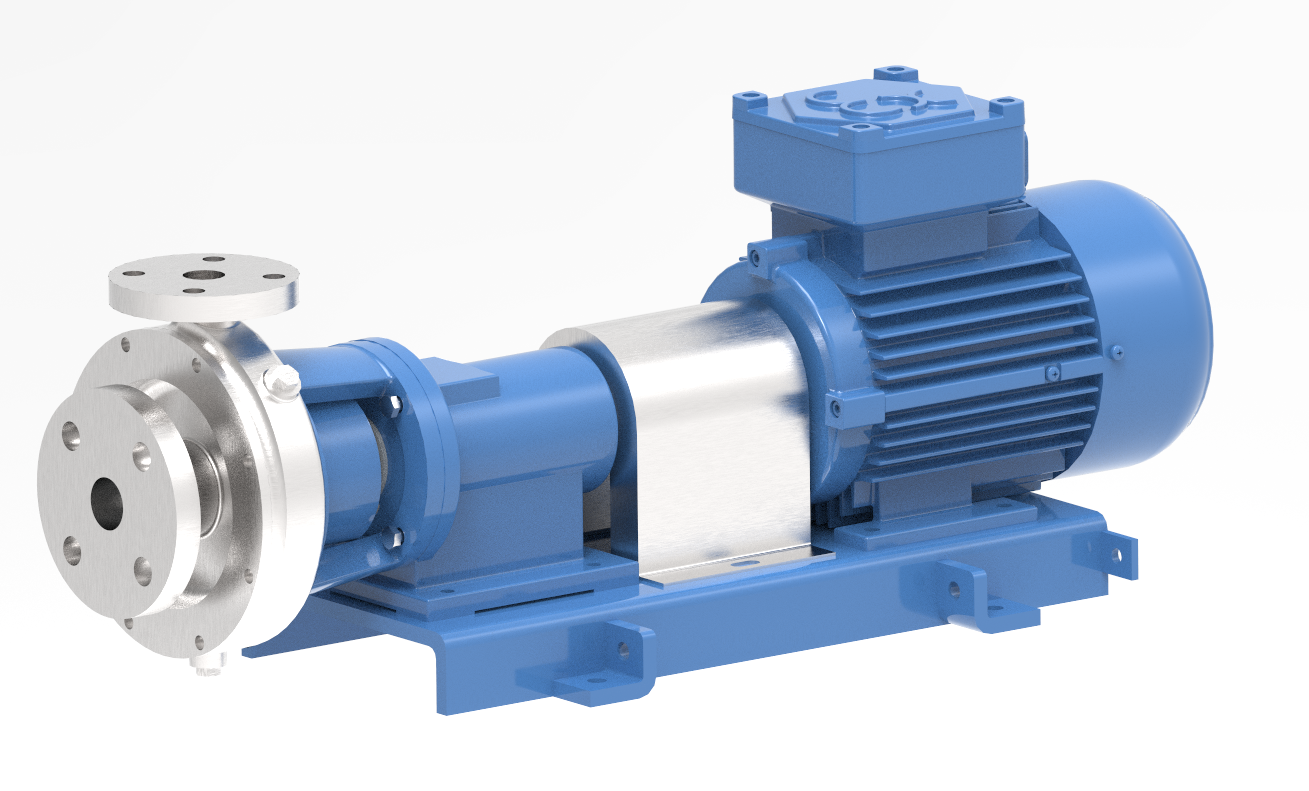

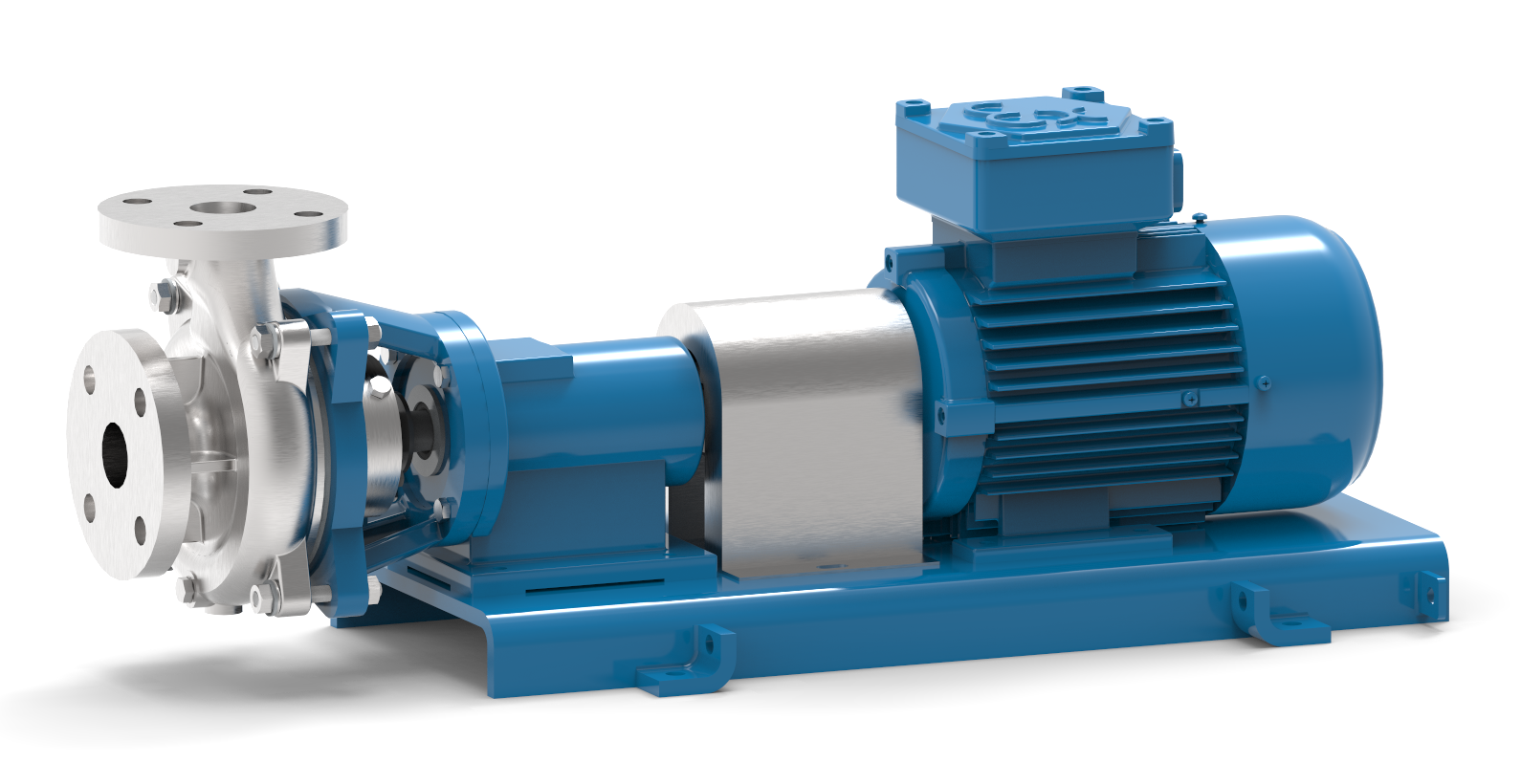

The EX-BX series centrifugal process pumps are specially designed for a wide range of uses in the chemical and fine chemicals industries – especially for difficult and/or corrosive products.

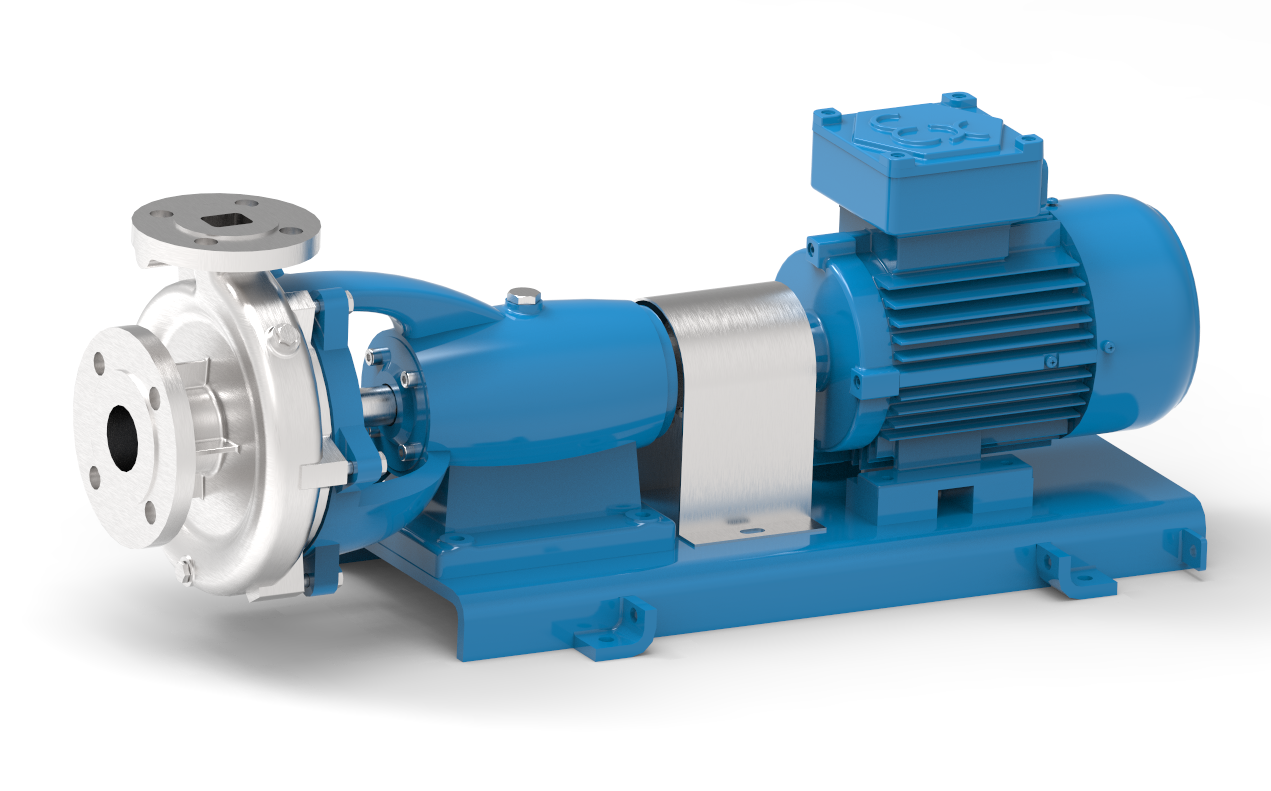

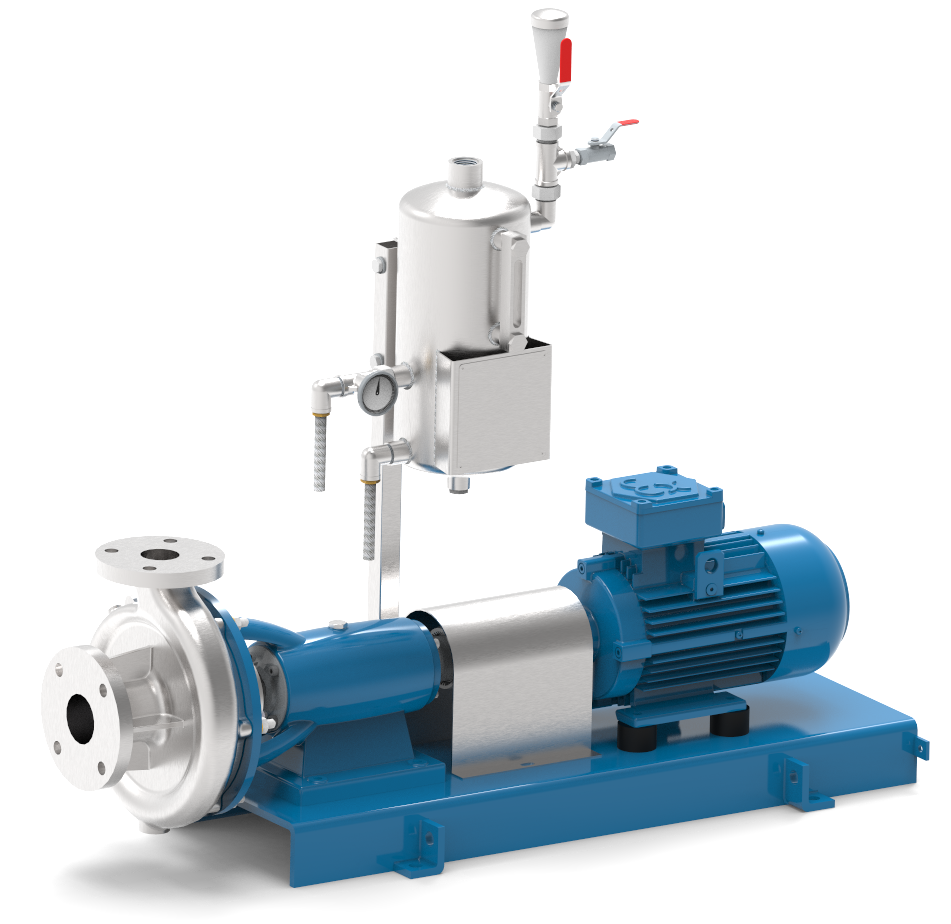

Because they are secured to baseplates, the EX-BX pumps can be used for a wide variety of industrial purposes. Assembly using spacer coupling makes maintenance much easier.

Different API Plan are available and All the mechanical seals are in conformity with DIN 24 960.

Chemical and fine chemicals industries – Pharmaceutical industry – Cosmetic industry – Paper-making industry – Nuclear industry – Integration companies – Cement works – Transferring corrosive liquids or solvents – Ultra-filtered, purified demineralised water or WFI – CIP solutions – Tank unloading…

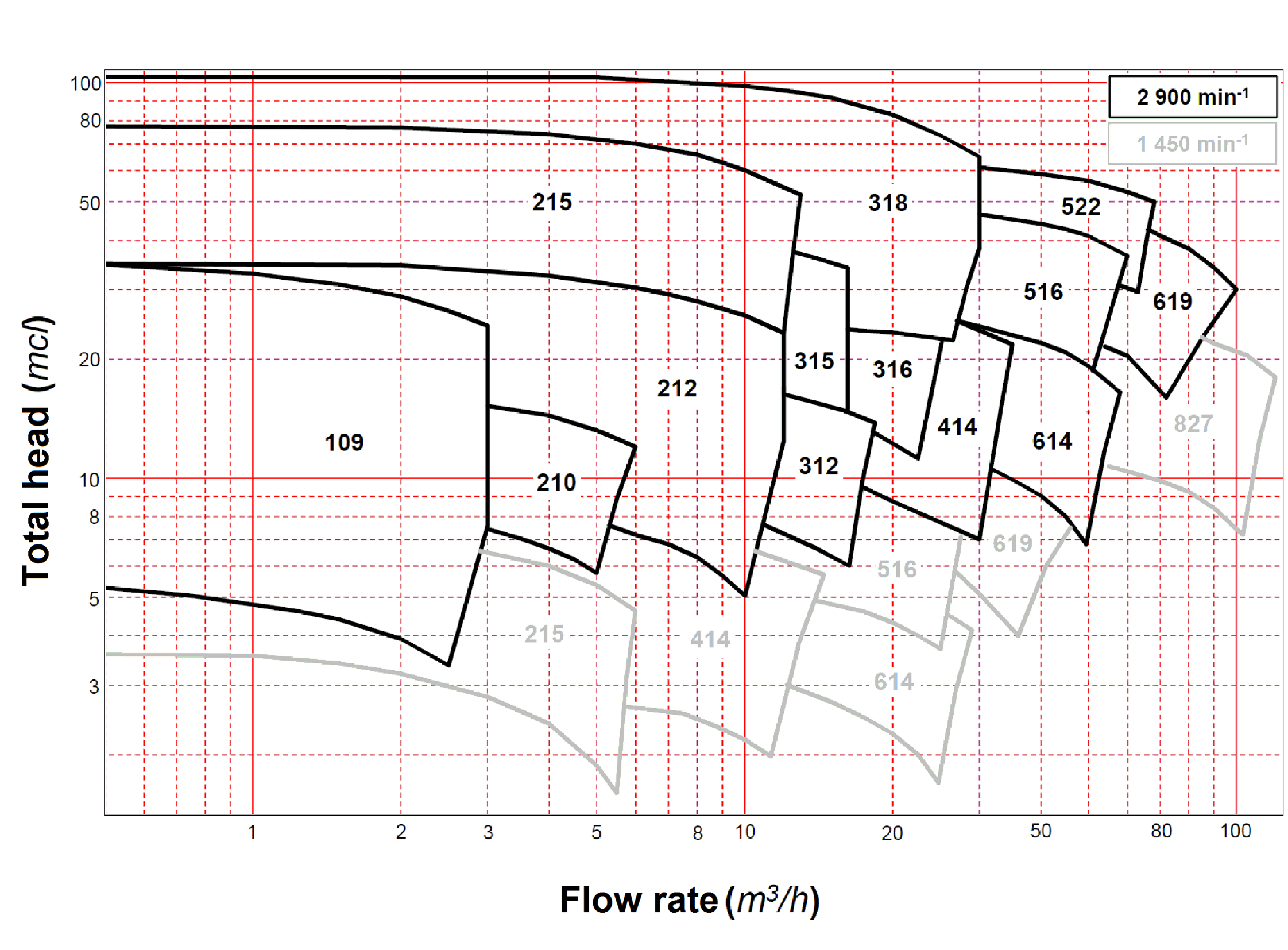

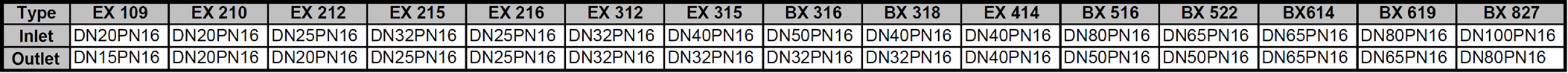

- Flow rate: 100 l/h to 100 m3/h

- Total head: < 105 m

- Operating temperature: – 40°C to + 200°C

- Operating pressure: < 10 bar

- Speed: < 3600 min-1

- ATEX certification: II 2 G II B T3/T4″

Please contact us to see the 1450 rpm/min speed selection curves.

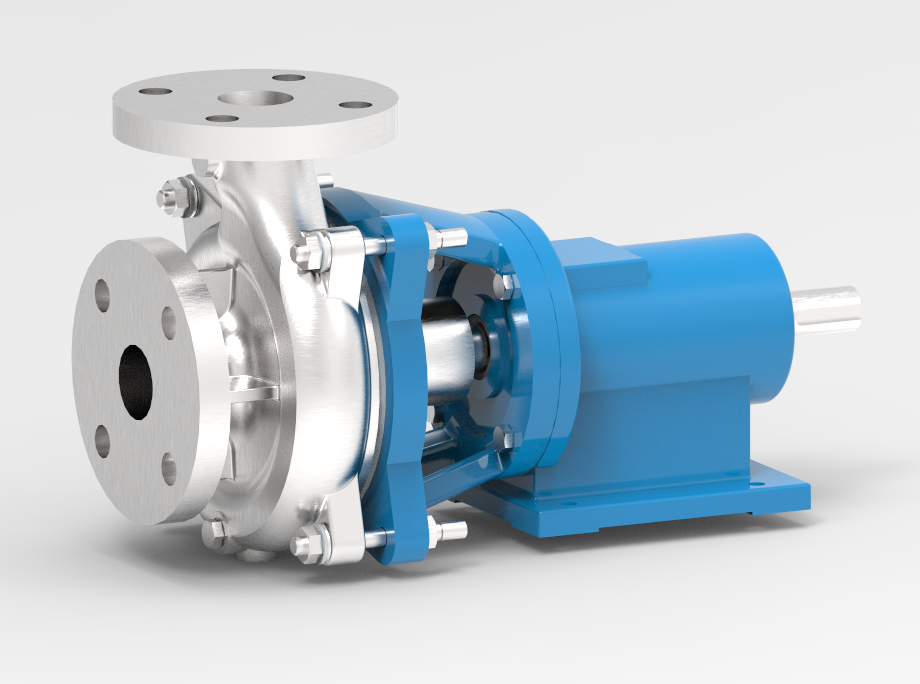

- Pump body 316L Stainless steel

- Cover/diffuser/flange 316L Stainless steel

- Impeller 316L Stainless steel

- Shaft 316L Stainless steel

- Gasket Graphite

To better respond to your requirements, our expertise in the metalworking industry is at your service: Stainless steel316, Hastelloy, Duplex…

- Assembly Simple, double back to back, or tandem mechanical seal

- Lubrication Process fluid

- Friction faces SiC/C

- O-ring FPM

We’ll help you define the best type of assembly and dynamic sealing adapted to your application.

Motor

- Three-phase (other voltage on request)

Paint

- Primer + high temperature paint