Some examples of customized work

In line with our product and marketing policy, POMPES GROSCLAUDE has based its development on keeping its human resources and design department in-house to be able to make individual or short runs of centrifugal pumps or skids that are more or less complex in nature.

Our design department uses both 2D (AutoCAD) and 3D (Solid Edge) modelling to design pumps or component assemblages created from specifications drawn up in collaboration with our customers.

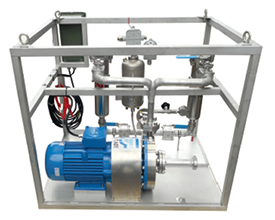

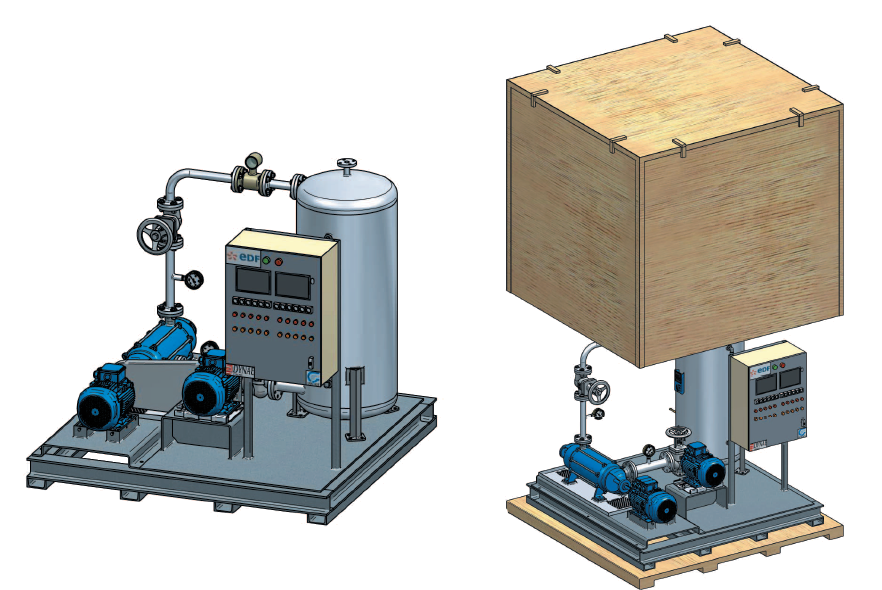

Filter and pump system

As part of the putting in place of a mobile system

to be used in different zones of a production plant

for the rinsing of several reactors, our client

asked us to design and manufacture:

- A 10m3/h at 60 mLC circulating pump compatible with suspended particles

- A mobile skid with filtration and motor protection for use in an ATEX zone

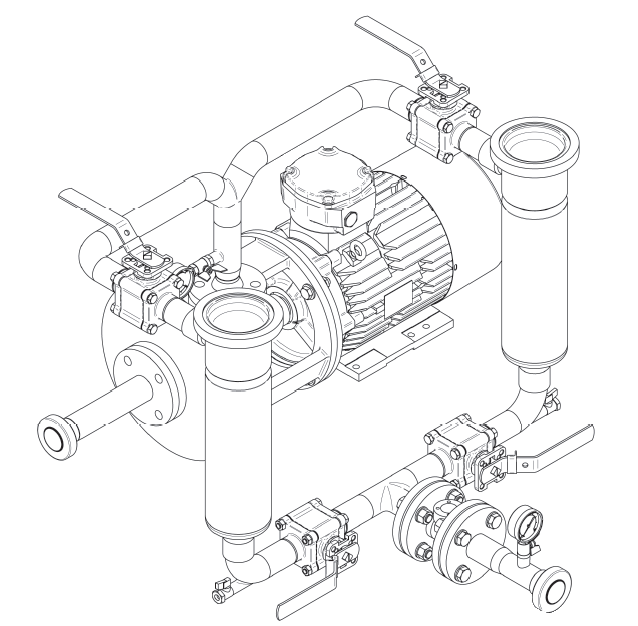

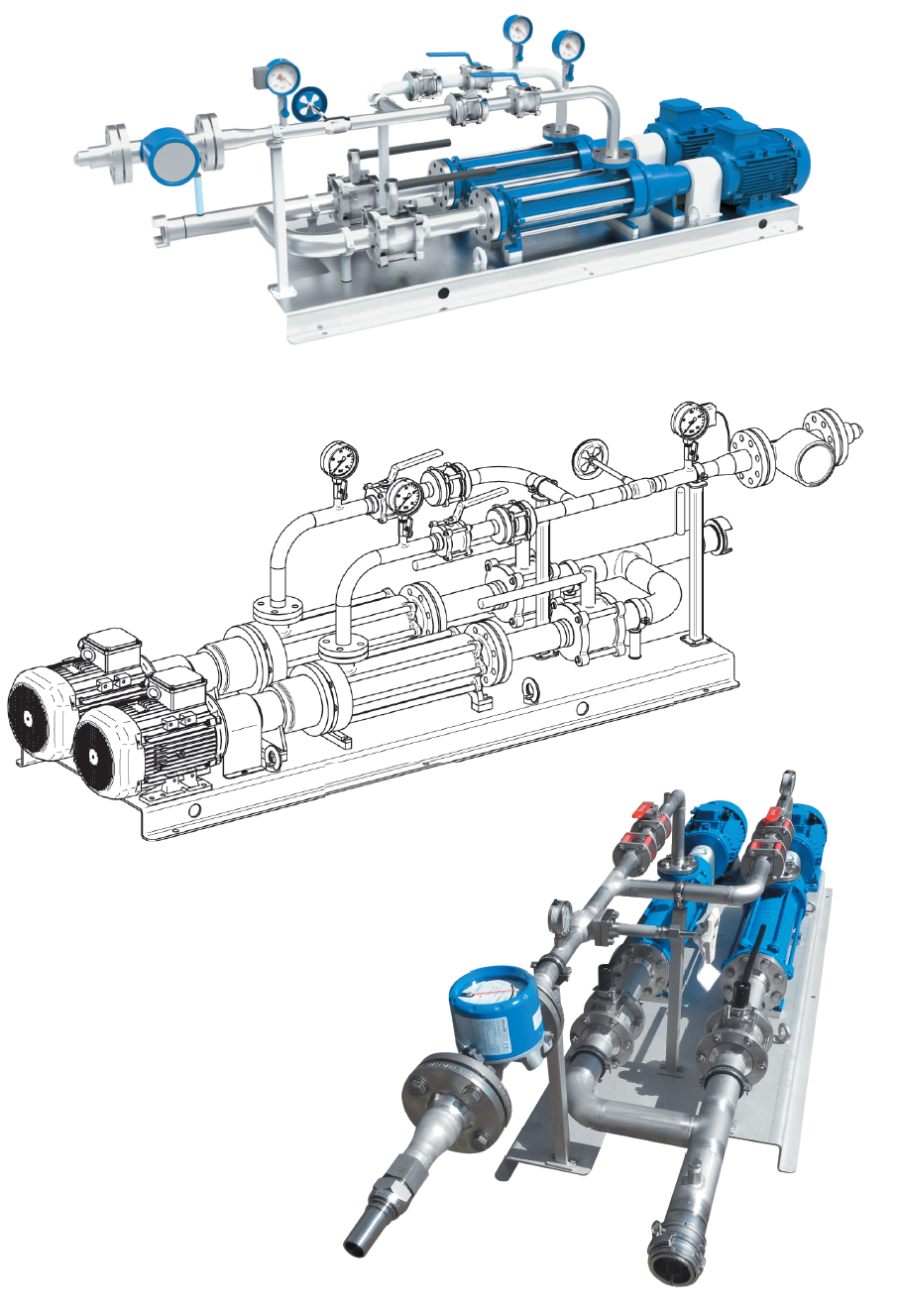

Mobile pumping skids

A CNRS (French National Scientific Research Centre) department contacted us for a pumping solution involving extreme conditions for both the transported liquid and the operating environment.

Operating temperatures:

-

- Exterior: – 50°C (the pump was to be installed in the Antarctic as part of a new ice drilling technique using a laser)

- Transported liquid: – 50°C (silicon oil used to cool the laser and enable the drilled ice to be brought back to the surface)

- The performance of the SEMA range lateral channel pump that we chose is 1.9 m3/h at 245 mLC. It has a magnetic drive to reduce maintenance in line with the operating environment of the pump.

As per the client’s requirements, we designed the pumping skid taking into account the constraints linked to transport (reduced size, maximum allowable weight etc.) and the operating environment.

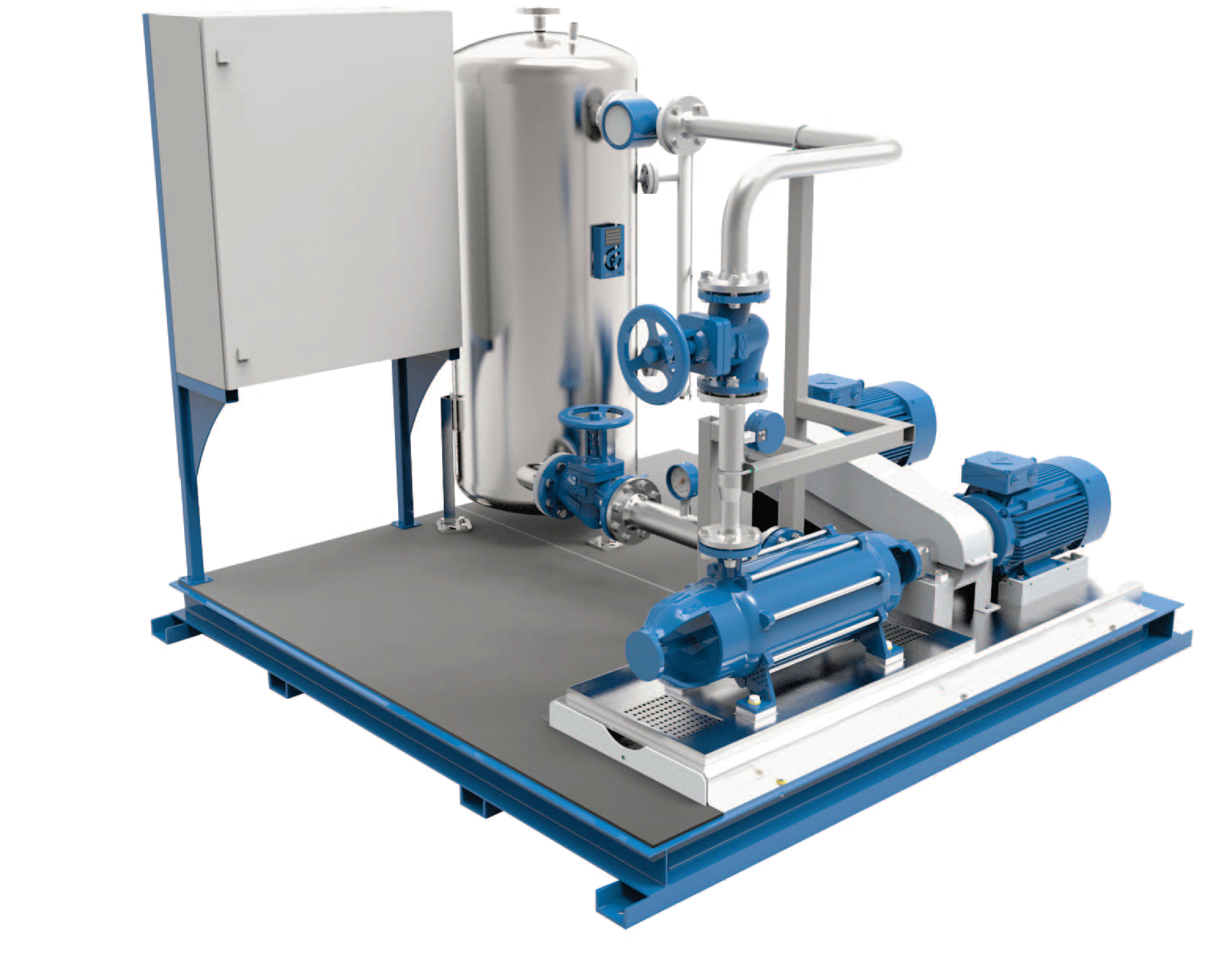

Complete system with tank, instrumentation and analysis equipment

As part of a design for a training centre, one of our clients

contacted us to design a piece of didactic equipment. It was to be used for training

teams spread out across several sites.

As the list of training subjects was quite long (vibration analysis, alignment

operations both by coupling and belt pulley assembly, maintenance, plotting a pump performance

curve etc.) a project was set in motion to create a complete system

which met the specifications that had already been set out.

The resulting system that we manufactured had the following characteristics:

The resulting system that we manufactured had the following characteristics:

- Creation of a complete didactic system, safe to use but also compact and easy to transport

- Design of a specific coupling system (enabling coupling with semi-elastic or belt pulley couplings)

- Creation of an assemblage of mobile motors enabling the production of vibrations and their analysis.

Sectors and main applications

Chemical and fine chemicals industries – Pharmaceutical industry – Cosmetic industry – Paper-making industry – Nuclear industry – Integration companies – Cement works – Transferring corrosive liquids or solvents – Tank unloading…