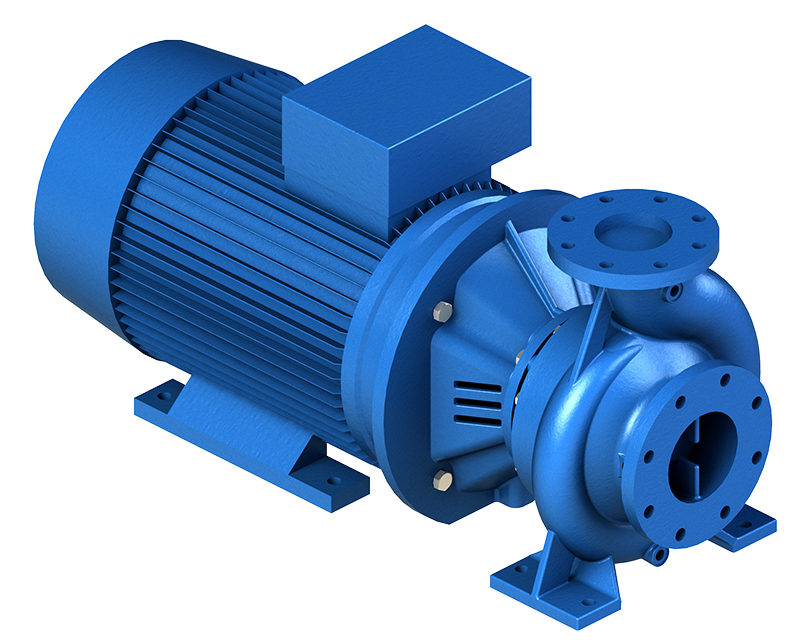

Standardised centrifugal pumps

The standard centrifugal monoblock pumps in the ALFA M series are specially designed for a large range of varied industry uses. Their hydraulic sizes and performance comply with norm

ISO 2858 or NF 44 121.

Thanks to a horizontal monoblock design, the ALFA M series pumps don’t take up a lot of space, making their integration into compact « »Skid » » types of assemblies easier. The pump and the motor (standard available on the market) form a monoblock joined together by flanges.

The standard centrifugal monoblock pumps in the ALFA M/S series are specially designed for a large range of chemical and fine chemical uses, and particularly for corrosive products that are clear or loaded or low-temperature products.Their hydraulic sizes and performance comply with norm ISO 2858 or NF 44 121.

Thanks to a horizontal monoblock design, the ALFA M/S series pumps don’t take up a lot of space, making their integration into compact « »Skid » » types of assemblies easier. The pump and the motor (standard available on the market) form a monoblock joined together by flanges.

Self-cooling, standardized centrifugal pumps in the ALFA R series are specially designed for a large range of use and mainly for heat transfer installations (< 350°C) on thermic oils.

Their hydraulic sizes and performance comply with the norm ISO 2858 or NF 44 121.

The ALFA R pumps are secured to a baseplate and are chosen for a wide variety of uses in the industry.Assembly using spacer coupling makes maintenance easier by keeping the hydraulic and electrical parts separated.

The standardized centrifugal pumps in the ALFA series can be employed for a wide range of uses, specifically for challenging sectors such as the chemical or petrochemical industries. They comply perfectly with ISO 2858 or NF 44 121 standards.

The slab which supports the pump can serve as tank cover, with a rising pillar for the part “liquid backflows”. According to your tank’s dimensions, the length under the laying plan can reach six meters if necessary.